There are a lot of advantages of the boxer engine layout: it has a lower center of gravity, it is intrinsically counter balanced, it is compact, etc. One of the downfalls of the turbocharged Subaru boxer motor is all the extra plumbing. The ports on the left head are as far away as they can be from the right head. It forces the manifolds runners to be long. For the EJ motors, the exhaust path is made to be a few feet long from the exhaust ports on the motor to the turbo. But, the place the turbo fairly close to the factory top mount intercooler (TMIC), so at least that plumbing is minimized to a foot or so. The FA20A DIT engine has super short exhaust runners before the turbo. It still has a TMIC, but it is better to have a shorter exhaust path to maintain the energy than have a shorter boost path.

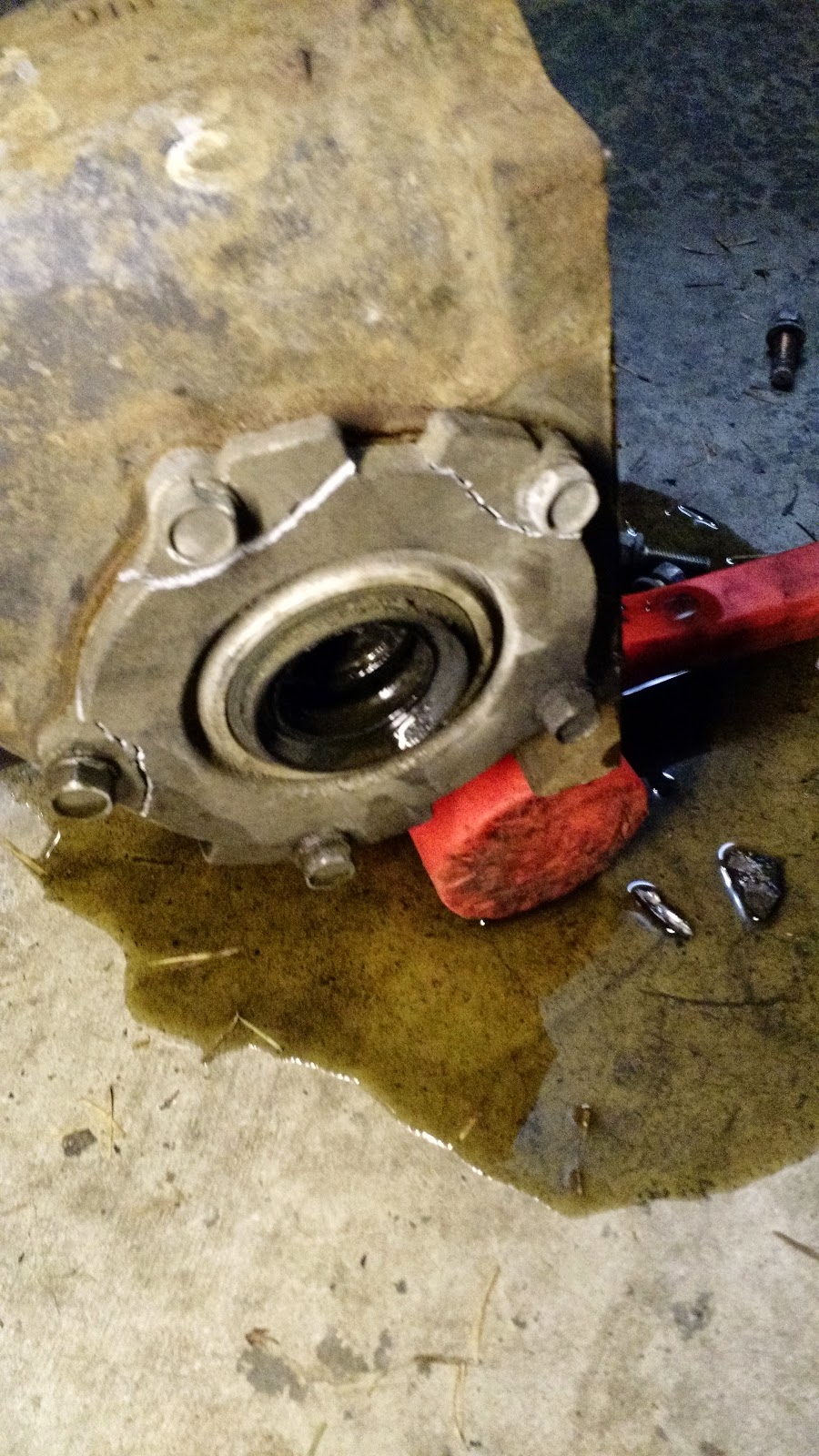

Here is the turbo off of the new 2015 WRX FA20 DIT motor:

There are a few problems with the TMIC. The first one is heat soak since it is right next to the turbo and engine. The second one is size; there is only so much space to put a larger TMIC. Also, you are limited by the scoop on the hood, and how well the splitter works getting the passing air through the intercooler.

A more optimal location is to have your intercooler on the front of the car. Many factory turbocharged cars have front mounted intercoolers (FMIC). That is where most cold air hits the car as you drive. It won't get heat soaked from the engine and turbo. Also, there is more space to put a very large intercooler.

At SEMA last year, I asked an engineer from a German intercooler company when is the intercooler too big. He said there isn't "too big" for intercoolers. That is mostly correct, but kind of an over simplification; however, the point of this post isn't to deep dive into intercoolers. :)

Anyway, a FMIC on a Subaru is useful because of the previously mentioned reasons. The down side is that it adds feet of extra piping which can increase turbo lag among other things.

We decided to run a FMIC on project Domino. There aren't exactly kits on the market that are made for a GM chassis and a GD motor, so we had to make our own.

Here is all of the extra piping that needed to be added for the FMIC setup.

Check out the size of the core! It is something like 32" x 12" x 3". It is a little ridiculous, but it is actually the perfect size to fill the void in the bumper cover. Plus, I have the German engineer on my side that it isn't too big. :) We drilled some holes on the lightened bumper beam to mount it, and the bottom part of the bumper beam had to be cut out a little for the IC pipes to make it through. There is no way that this would fit with the factory USDM bumper beam. FYI, the JDM bumper beam doesn't have the lower part that I had to cut off.

Since we added an new 32" x 12" x 3" volume before the radiator, the bumper cover had to be trimmed. How much? About 4".

Here are some of the leftovers to give you an idea how much had to be cut away:

All cut out:

This is what it looks like mounted up. There is literally no extra space in the bumper cover with this intercooler.

Additionally, we have been making good progress with the wiring. The harness is all together and mounted. We are in the testing phase right now before we plug the ECU in.

Wednesday, January 21, 2015

R160 + 400 ft*lbs = Complete Failure

Ever wonder why we swapped out the whole drive train in Domino? The stock RS 5-speed drive line was mechanically working just fine. The reason is because we are targeting 400 hp and 400 ft*lbs at the wheels. The STI 6-speed + R180, and the 5x114 axles we are using can reliably run that kind of power without drama. 5-speeds cannot.

One of our other cars has been running with a stock 5-speed drive line with 460 hp and 400 ft*lbs at the crank. Note: it was tuned *down* to 400 ft*lbs to improve the longevity of the drive line.

One of our other cars has been running with a stock 5-speed drive line with 460 hp and 400 ft*lbs at the crank. Note: it was tuned *down* to 400 ft*lbs to improve the longevity of the drive line.

Subscribe to:

Comments (Atom)